Services and Equipment

Manufacturing, Assembling, Treatment

Printed Circuit Boards and Printing Masks

Services

- Manufacturing of Herstellung von phot masters for PCB production

- Manufacturing of one-sided, double-sided and multilayer PCBs (up to 6 layers) including through hole metallization

- Manufacturing of copper printing masks by etching

Equipment

- Equipment for manufacturing of PCBs and printing masks

- Computer controlled mill-drill-plotter Bungard CCD, maximum rotation speed 60.000 rot./min, drilling diameter 0.3 - 4 mm

- PCB brush engine, Bungard

- Galvanic Compakta for tenting technology, Bungard, maximum workpiece size 300 mm x 400 mm

- Etching machine, Bungard, copper-II-chloride

- Stripper sodium hydroxide

- Rigid resist laminators (Hot rol), Bungard

- phot. etching resist 40 µm, width 300 mm

- phot. solder mask 65 µm, width 400 mm

- Exposurer, Bungard EXP 8000

- Multi layer laminator MLP 20

Thick Film Technology

Services

- Testing of new materials and development of technologies

- Prototyping and manufacturing of examples

- Characterization of thick film components and layer systems

Equipment

- Mask preparation

- photo plotter (Gerber format)

- screens with emulsion (steel and polyester canvas, standard / fine)

- copper masks (double sided etched)

- steel masks (laser cut)

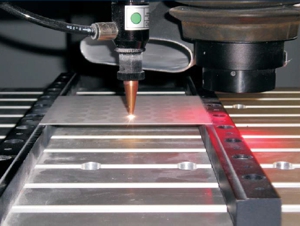

- Laser technology

- drilling of vias in ceramic substrates and polymer foils

- cutting and scribing of outlines for panel separation

- resistor trimming

- Screen printing technology

- MPM-SPM (with vision system)

- EKRA X5 STS

- Sintering technology

- programmable batch furnace ATV PEO 603

- zone furnace BTU up to 1100 °C

- Possible technologies

- CERMET thick film technology on Al2O3-ceramics

- Low Temperature Cofired Ceramic Technology – LTCC

- Polymer thick film technology on organic flex substrates

Prototyping and Module Assembly

Mehrkopf-Drahtbonder 56xx

SMD-Montagelinie (Schablonendrucker, Bestückautomat, Konvektionslötanlage)

Services

- Assembly of electronic modules, prefered in SMD technology

- First- and second-level interconnect technologies

Equipment

Micro assembly:

- Ultrasonic and thermosonic wire bonder F&K Delvotec 54xx and 56xx

- Flip chip bonder

- Fineplacer

Application of interconnect materials:

- Mask printing equipment EKRA X3

- Dispensing machine Martin

Placement of components:

- SMD-assembling machine SIPLACE SX1

- SMD-aasembling machine Fuji NXT-II

- Places for manual assembly

Soldering technologies:

- Convection reflow soldering equipment Rehm V8 2.1

- Wave soldering equipment Seho GoWave

- Vapor phase soldering equipment IBL

- Rehm Condenso XM

- Selective soldering equipment (light) ATN economic A400

Laser treatment of materials

Laser station

Services

- Material treatment of ceramics and thin metal foils

- Thick film resistor trimming

- Drilling and cutting

- Laser soldering

- Laser micro welding

Equipment

- 3D-Micromac microCUTms10.6: CO2 laser, 200 W + fibre laser, power 20 W

- Welding laser LSW 4001

Measuring

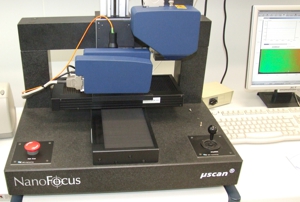

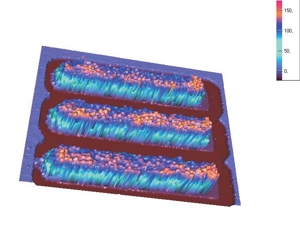

Geometrical characterization

3D profiling NanoFocus µscan with different sensors

Measurement of a printed solder volume

Services

- contact-free topological measurement of surfaces

- determination of roughness

- volume calculation

- needle-contact topoligical Measurement of surfaces

Equipment

- Laser profilometer NanoFOCUS µScan AF2000

- Measurement system NanoFOCUS µSurf

- NanoFOCUS µSprint

- MarSurf CP select

- 3D-coordinates measurement equipment PMC 500

- Two-coordinates Measurement microscope ZKM 01-250C (Carl Zeiss)

- Bruker DektakXTA

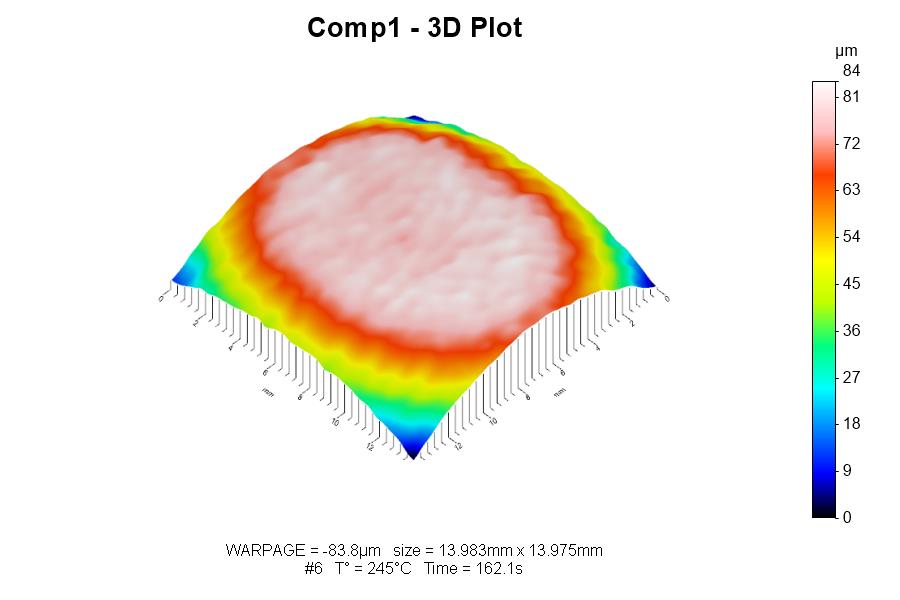

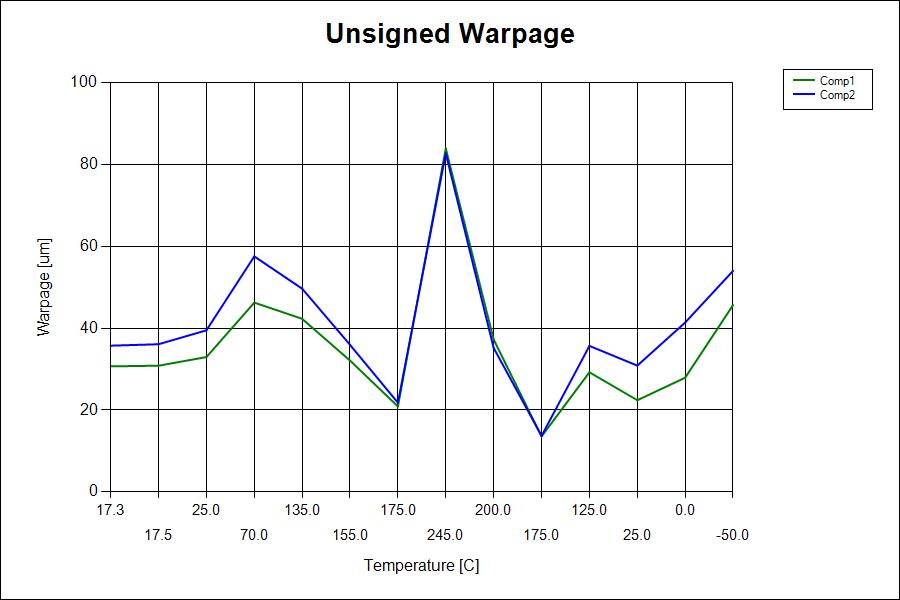

Dynamic Topography Measurement

BGA topography @ 245°C

Coplanarity mismatch, unsigned

Services

Measurement of topography and deformation and its changing on flat objects under changing temperature conditions (e.g. simulation of soldering temperature profile up to 280°C, temperature cycles down to -50°C)

Sample objects:

- bare Printed Circuit Boards

- components (BGA, LGA, QFP, QFN)

Sample objects which need special preparation:

- SMD connectors

- assembled PCB

other objects on request (please deliver object pictures and dimensions before)

Equipment

- Insidix TDM Compact II

- Objects up to (300 x 200) mm2

- Infrared heating (max. temperature gradient 3K/s)

- Active cooling (max. temperature gradient -3K/s)

- Temperature range: -50°C ... 300°C

- Accuracy z-direction: 1,5 µm repeatabilityt

- Resolution vs. measurement area (FOV = Field of View)

- 53 µm @ (195 x 155) mm²

- 31 µm @ (110 x 90) mm²

- 10 µm @ (37 x 30) mm²

- 3 µm @ (12 x 10) mm²

Physical characterization

Rheology

Services

- Determination of rheological behaviour of pastes

- Investigation of the influence of surface treatment, in example on the releasing behaviour of printing screens and masks

Equipment

- Rheometer HAAKE RheoStress 600

- VC Motor controlled

- mimimum torque 0.5 µNm

- angle resolution of 0.012 µrad

- Peltier-tempered plate-conus-system

- T=(-60 – 185) °C

- Measurement in three modes:

- shear stress presetting (CS-mode)

- rotation speed presetting (CR-mode)

- deformation-controlled (CD-Modus)

- VC Motor controlled

Contact angle measurement

Services

- Contact Angle measurement

- Calculation of surface tension and surface energy of packaging materials

- Statistical analysis and failure analysis

Equipment

- Contact angle measurement equipment dataphysics OCA 20

Analyze

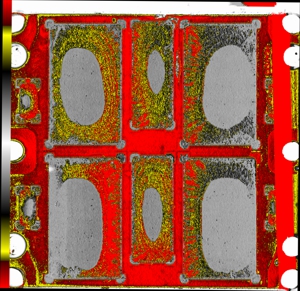

Scanning acoustic microscopy

Scanning acoustic microscope

Failure detection in DCB modules

Service

- Non-destructive inspection of prototypes and samples of packaged and unpackaged components, devices and substrates.

- Layer by layer detection of failures like delaminations, gas inclusions, cracks and selective micro defects, especially of laminates, large area adhesions (e.g. heatsinks) and DCB substrates.

- Run-time analysis to describe material inhomogeneity.

- Ultrasonic scans are documented as files or color printed images.

Equipment

Ultrasonic microscope SONOSCAN C-SAM® Gen6™

- Changeable transducers with the following frequencies and lateral resolutions:

- 10 MHz: 250 µm

- 15 MHz: 175 µm

- 20 MHz: 125 µm

- 30 MHz: 75 µm

- 50 MHz: 50 µm

- 60 MHz: 30 µm

- 100 MHz: 25 µm

- 230 MHz: 10 µm

- Investigation depth up to some millimeters depending on the frequency and the material

- Investigation methods C-Scan, Q-BAM™, THRU-Scan™

- VRM™ (complete storage of echo signals of the specimen), regenerating of defect images of any layer, extraction of three-dimensional information, run-time topography

- Coupling medium: de-ionised water

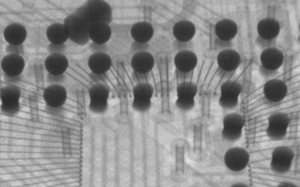

X-ray diagnostics

Radiography of BGA solder joints using oblique view

Volume model of a tomography of a passives solder joint

X-ray radiography

Service

Equipment

- Non-destructive inspection of electronic devices and modules, especially with high contrastive materials (solder, metallisation), e.g.:

- Standard- and fine-pitch-SMT and THT solder joints

- BGA-, COB-, CSP- and Flip-Chip solder joints

- Missing and imperfect solder joints

- Displacement

- Shorts

- Solder joint analysis (voids)

- Multilayer PCB

- X-ray microscope phoenix|x-ray nanome|x

- high resolution vertical or oblique view up to 70°

- high resolution real time image processing or alternatively digital detector

- CCD camera: 1126 x 1600 pixel, resolution 12 bit

- Digital detector: 1000 x 1000 pixel, resolution 14 bit

- geometrical magnification: > 1.000 times

- minimal detail visibility: 400nm

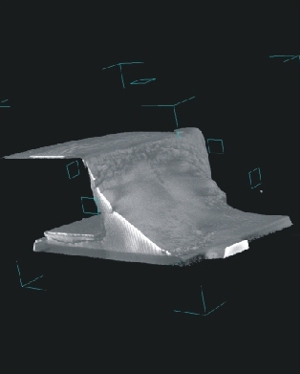

X-ray Computer Tomography

Services

- Volume analysis and reconstruction of electronic devices and modules

Equipment

- X-ray Computer Tomography equipment nanotom

- open nanofocus tube with tungsten target

- acceleration voltage: 10 – 180kV / 15W

- beam current: 5 – 1.000µA

- precision manipulation on a granit base

- high resolution digital detector with 2.400 x 2.400 Pixel, 12 bit

- pixel size: 50µm x 50µm

- minimal voxel size: < (500nm x 500nm x 500nm)

- geometric magnification: 1,7-times to 1.000-times

- maximal specimen size/ weight: h = 150mm, d = 120mm, m = 1kg

Metallographic preparation of packages

Services

- Preparation of a target layer

- Analysis of microstructures, cracks, delaminations and voids (e.g. for packaging qualification after thermal-mechanical stress)

- Measurement of structure size, like intermetallics, lengths, layer thicknesses

- Documentation and reporting of the results

Equipment

- Grinding and polishing: TegraSystem (TegraForce-5, TegraPol-35)

- Precision sectioning saws: IsoMet 1000 (bis 1000 RPM), Accutom-2 (3000 RPM)

- Microscopy: Leica DM4000 M (max. magnification 1000x) and digital camera (2080x1544 pixel)

- Reflected light methods: bright field, dark field, polarized light, differential

interference contrast

- Reflected light methods: bright field, dark field, polarized light, differential

- Database image management system

Storage testing, accelerated aging

Service

- Temperature profile detection

- Off-line measurement

- On-line measurement

- Zero-Ohms resistance measurement

- Failure detection with defined shut down of cycle chambers

- Voltage measurement

Equipment

- Temperature test chamber

-

- Single chamber system Feutron TPK 600

- Temperature range: -70 °C to 180 °C

- Temperature gradient: 10K/min (-55 °C to 150 °C)

- Power cycle chamber

- Two chamber system Feutron TSK 200

- Hot chamber: 10 °C to 200 °C

- Cold chamber: -75 °C to 180 °C

- Zerol-Ohm measurement system

- Four-point resistance measurement

- Software controlled

- Temperature triggered

- Keithley-Delta-Mode System

- Nano volt meter Keithley Modell 2182A

- Current source Keithley Modell 6121

- 128 channel multiplexer

- Voltage measurement

- Four-point resistance measurement

- Isothermal storage

- Temperature range: -80 °C to 300 °C

Note

Additional information about equipment and services and how you can use it can be found following the links below: