The technological development of our society might be characterized with the “Internet of Things (IoT)”. Electronics packaging provides the hardware in many products being part of such an extended network. Nearly everything in future will be connected with a more or less powerful electronic hardware to the network or to the IoT and “the network of humans and things”. In order to ensure proper function of the IoT the electronics (hardware) and the control programs and protocols (software) drastically need to be advanced.

We have to ensure only smallest delays in signals and reactions in order to allow the advanced services to operate, for example autonomous driving vehicles or remote surgery in a hospital. Only if delays less than 1 millisecond can be achieved, then the IoT is considered “realtime” for such services and is then called “tactilel internet”.

TU Dresden contributes to the development of the tactile internet. IAVT supports with the development of advanced electronics packaging concepts in the frame of the special research project of the German Research Foundation (Deutsche Forschungsgemeinschaft (DFG) SFB 912, Highly Advanced Energy Efficient Computing (HAEC) and of the European Science Foundation (ESF) and the Saxonian Development Bank (SAB) funded Young Researchers Group "Communication infrastructres for Atto networks in 3D chip stacks" Atto3D.

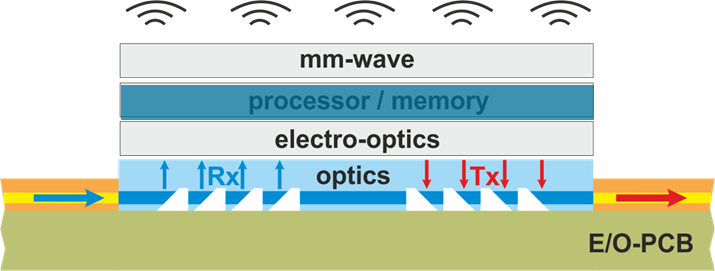

3D Research activities in the frame of the SFB 912 HAEC at the TU Dresden

The network nodes of the future for 5th and 6th generation of the IoT and the tactile internet will have to be extremely powerful with high bandwidth, throughput and extremely small delay times. At present the network nodes already show very high energy consumption. It is expected that the energy consumption will increase further extremely if the concepts of the network nodes are not advanced. Therefore, in the frame of the SFB 912 HAEC energy-adaptive network nodes of the future are investigated.